.

.

WARNING: This information is provided as a service to our potential customers, but Infiltec, Inc. can not be responsible for its use or misuse.

The most recent page updates are marked by

.

.

INDEX TO THIS PAGE:

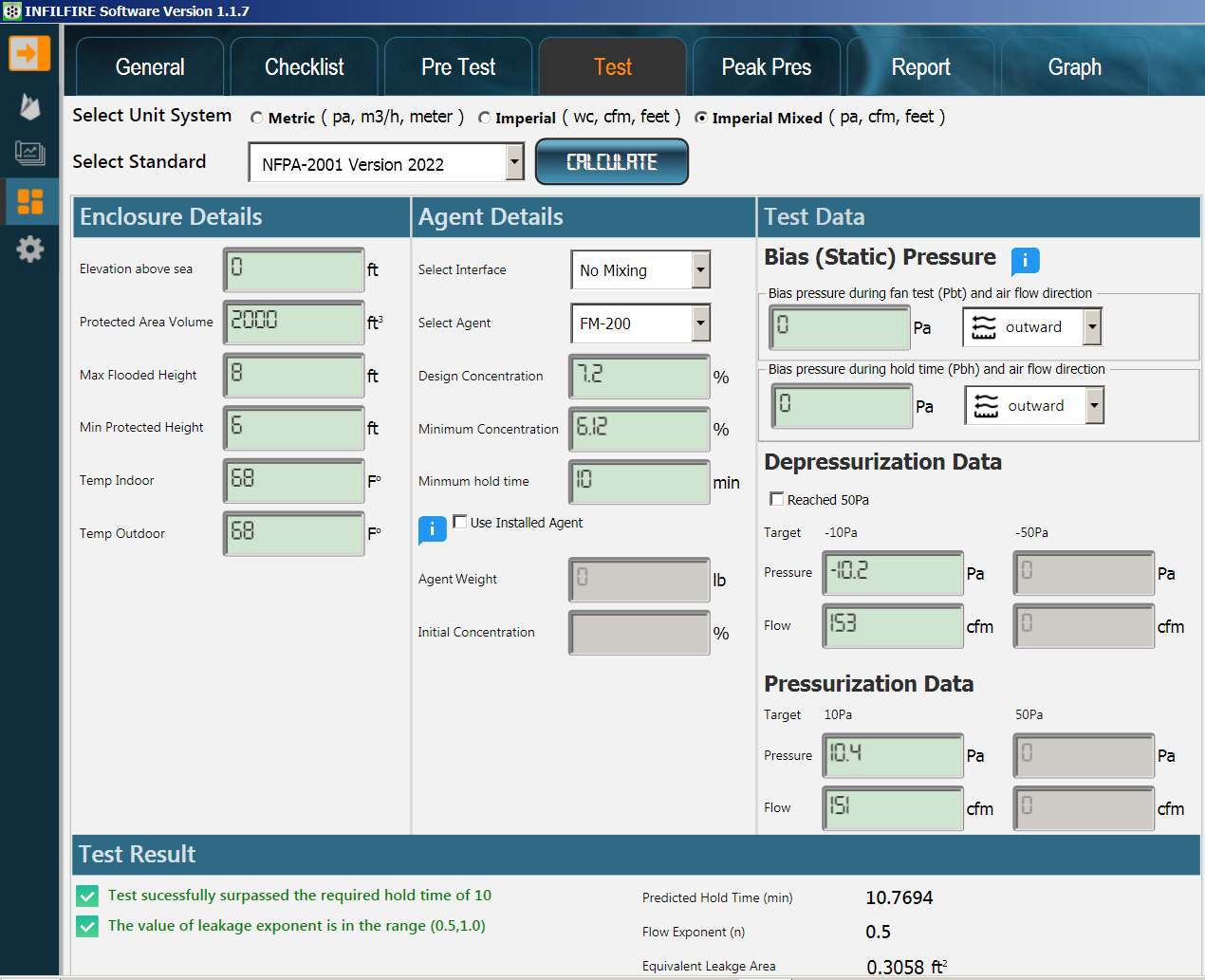

NEW Windows Software for NFPA 2001 2022 for the Clean Agent Enclosure Integrity Test

NEW Windows Software for NFPA 2001 2022 for the Clean Agent Enclosure Integrity Test

Introduction to Fire Protection Enclosure Air Leakage Testing

Blower doors are large calibrated fans that were developed in the 1970s to test the air leakage of houses for energy conservation work, but the recognition of the stratospheric ozone problem in the 1980s led to a new application of this airtightness testing technology. Halon 1301, a gaseous fire protection agent, was found to have one of the highest ozone depletion potentials, and a significant source of halon discharge into the environment was found to come from the testing of halon total flooding fire protection systems. In a typical application, such as a computer room, the acceptance test for the system involved a "discharge test" where the fire protection system was triggered, a full load of halon was discharged into the room, and the residence time for the halon in the room was measured. When the ozone depleting potential of these acceptance tests was discovered, there was a need for a new type of acceptance test that did not involve the discharge of halon 1301 into the atmosphere.

Infiltec's experience in air leakage test equipment development enabled it to invent a test that solved this problem. The "enclosure integrity test" involves measuring the total area of the holes in the protected room with a blower door, assuming a worst-case distribution of leaks across the enclosure surface, and computing the worst-case leakage of the fire protection gas mixture through those holes. David Saum and Arthur Saum of Infiltec were issued US patent #5,128,881 Means and Methods for Predicting Hold Time in Enclosures Equipped with a Total Flooding Fire Protection Fire Extinguishing System for this work. This test was incorporated into the NFPA 12A Standard for halon 1301, and it has since been modified for halon alternative gases in the NFPA 2001 Standard.

Infiltec is a worldwide supplier of air leakge test equipment for the

measurement of fire protection enclosure integrity, and it

also provides calibration and training.

![]()

HOW BIG A ROOM CAN YOU TEST WITH ONE BLOWER DOOR?

The maximum fire enclosure volume that can be tested depends primarily

on the following parameters:

Here are some sample calculations with assumptions specified:

| Extinguishing Agent | 6.0m (19.7ft) Maxium | 6.0m (19.7ft) Maxium | 3.0m (9.8ft) Maxium | 3.0m (9.8ft) Maxium |

|---|---|---|---|---|

| @ NFPA 2001 Category C Protect | 5.1m (16.7ft) Minimum | 4.5m (14.8ft) Minimum | 2.5m (8.2ft) Minimum | 2.0m (6.6ft) Minimum |

| % Concentration | 85% Protected Height | 75% Protected Height | 83% Protected Height | 66% Protected Height |

| FM-200 (HFC-227ea) @ 7% | 5150 m3 (182,000 ft3) | 3000 m3 (106,000 ft3) | 3300 m3 (117,000 ft3) | 1550 m3 (54,700 ft3) |

| INERGEN (IG-541) @ 38.5% | 2500 m3 (88,000 ft3) | 1500 m3 (53,000 ft3) | 1570 m3 (55,000 ft3) | 760 m3 (27,000 ft3) |

| HALON 1301 @ 6% | 4500 m3 (159,000 ft3) | 2600 m3 (92,000 ft3) | 2800 m3 (99,000 ft3) | 1350 m3 (48,000 ft3) |

| NOVEC-1230 (FK-5-1-12) @ 4.7% | 5840 m3 (206,000 ft3) | 3400 m3 (120,000 ft3) | 3700 m3 (131,000 ft3) | 1750 m3 (62,000 ft3) |

| ARGONITE (IG-55) @ 42.7% | 2500 m3 (88,300 ft3) | 1450 m3 (51,200 ft3) | 1570 m3 (55,400 ft3) | 750 m3 (26,500 ft3) |

| FE-25 (HFC-125) @ 9.0% | 4700 m3 (166,000 ft3) | 2750 m3 (97,000 ft3) | 2970 m3 (105,000 ft3) | 1410 m3 (50,000 ft3) |

| Extinguishing Agent | 6.0m (19.7ft) Maxium | 6.0m (19.7ft) Maxium | 3.0m (9.8ft) Maxium | 3.0m (9.8ft) Maxium |

|---|---|---|---|---|

| @ NFPA 2001 Category C Protect | 5.1m (16.7ft) Minimum | 4.5m (14.8ft) Minimum | 2.5m (8.2ft) Minimum | 2.0m (6.6ft) Minimum |

| % Concentration | 85% Protected Height | 75% Protected Height | 83% Protected Height | 66% Protected Height |

| FM-200 (HFC-227ea) @ 7% | 15450 m3 (546,000 ft3) | 9000 m3 (318,000 ft3) | 9900 m3 (351,000 ft3) | 4650 m3 (164,100 ft3) |

| INERGEN (IG-541) @ 38.5% | 7500 m3 (284,000 ft3) | 4500 m3 (159,000 ft3) | 4710 m3 (165,000 ft3) | 2289 m3 (81,000 ft3) |

| HALON 1301 @ 6% | 13500 m3 (477,000 ft3) | 7800 m3 (276,000 ft3) | 8400 m3 (297,000 ft3) | 4050 m3 (144,000 ft3) |

| NOVEC-1230 (FK-5-1-12) @ 4.7% | 17520 m3 (618,000 ft3) | 10200 m3 (360,000 ft3) | 11100 m3 (393,000 ft3) | 5250 m3 (186,000 ft3) |

| ARGONITE (IG-55) @ 42.7% | 7500 m3 (26,900 ft3) | 4350 m3 (153,600 ft3) | 4710 m3 (166,200 ft3) | 2250 m3 (79,500 ft3) |

| FE-25 (HFC-125) @ 9.0% | 14100 m3 (498,000 ft3) | 8250 m3 (291,000 ft3) | 8910 m3 (315,000 ft3) | 4230 m3 (150,000 ft3) |

| Extinguishing Agent | 6.0m (19.7ft) Maxium | 6.0m (19.7ft) Maxium | 3.0m (9.8ft) Maxium | 3.0m (9.8ft) Maxium |

|---|---|---|---|---|

| @ NFPA 2001 Category C Protect | 5.1m (16.7ft) Minimum | 4.5m (14.8ft) Minimum | 2.5m (8.2ft) Minimum | 2.0m (6.6ft) Minimum |

| % Concentration | 85% Protected Height | 75% Protected Height | 83% Protected Height | 66% Protected Height |

| FM-200 (HFC-227ea) @ 7% | 56650 m3 (2,002,000 ft3) | 33000 m3 (1,166,000 ft3) | 36300 m3 (1,287,000 ft3) | 17050 m3 (601,700 ft3) |

| INERGEN (IG-541) @ 38.5% | 27500 m3 (968,000 ft3) | 16500 m3 (583,000 ft3) | 17270 m3 (505,000 ft3) | 8360 m3 (297,000 ft3) |

| HALON 1301 @ 6% | 49500 m3 (1,740,000 ft3) | 28600 m3 (1,012,000 ft3) | 30800 m3 (1,089,000 ft3) | 14850 m3 (528,000 ft3) |

| NOVEC-1230 (FK-5-1-12) @ 4.7% | 54240 m3 (2,266,000 ft3) | 37400 m3 (1,320,000 ft3) | 40700 m3 (1,441,000 ft3) | 19250 m3 (682,000 ft3) |

| ARGONITE (IG-55) @ 42.7% | 27500 m3 (264,900 ft3) | 15950 m3 (563,200 ft3) | 17270 m3 (609,400 ft3) | 8250 m3 (291,500 ft3) |

| FE-25 (HFC-125) @ 9.0% | 51700 m3 (1,826,000 ft3) | 30250 m3 (1,067,000 ft3) | 32670 m3 (1,155,000 ft3) | 15510 m3 (550,000 ft3) |

Please email Infiltec or phone (540) 943-2776 if you have a other test parameters that you would like to have evaluated, or if you have questions or comments.

The Infiltec Checklist for a Pretest Enclosure Inspection.

![]()

The Infiltec Checklist for Performing an Enclosure Integrity Test

![]()

Click on this Image to Enlarge

Latest Infiltec Infilfire Software Features as of August 2023:

![]()

Infiltec Enclosure Integrity Test Instruments and Prices

Infiltec offers digital models for the highest accuracy measurements, and analog models that meet all current test standards:

The Infiltec dual digital E3-A-DM4 combines the latest in low pressure electronic sensors, embedded processor and digital display technology to produce the most accurate, easy-to-use Enclosure Integrity Test Instrument.

Digital E3-A-DM4 Features:

| MODEL | DESCRIPTION | PRICE |

|---|---|---|

| E3-A-DM4-110 |

Infiltec Digital Blower Door

includes a fiberglass fan,

aluminum door panel with nylon cover and case,

DM4 Micro-Manometer, controls, calibration certificate, manual & case.

The DM4 Micro-Manometer features digital flow and pressure measurement,

leakage area (ELA) measurement, and dual auto-zeroing sensors for simultaneous

flow and measurements. The resolution is 0.1 Pa and 0.001" wc, the range

is ±1250.0 Pascals (±5.000" wc), and the

pressure accuracy is ±1% of reading or ±0.1 Pascal digit, whichever is greater.

The DM4 is calibrated for use with the E3 blower door, the Infiltec

DL1 duct leakage tester, and Pitot tubes. Flow, pressure, and leakage

area can be displayed in US, metric, or mixed units. Electronics are

110VAC/60 Hz. Options include software, fan covers, and door expander kit.

Enclosure integrity test capacity for one E3 fan is up to

5150 m3 (182,000 ft3) for FM-200,

2500 m3 (88,000 ft3)) for INERGEN,

4500 m3 (159,000 ft3) for HALON 1301,

5840 m3 (206,000 ft3) for NOVEC-1230,

2500 m3 (88,300 ft3) for ARGONITE, and

4700 m3 (166,000 ft3) for FE-25.

Calibration certificate included that meets NFPA 2001-2012, and ISO 14520-2012 standards.

Multiple fan systems are available for larger enclosures.

Specifications

Infiltec Digital Blower Door

includes a fiberglass fan,

aluminum door panel with nylon cover and case,

DM4 Micro-Manometer, controls, calibration certificate, manual & case.

The DM4 Micro-Manometer features digital flow and pressure measurement,

leakage area (ELA) measurement, and dual auto-zeroing sensors for simultaneous

flow and measurements. The resolution is 0.1 Pa and 0.001" wc, the range

is ±1250.0 Pascals (±5.000" wc), and the

pressure accuracy is ±1% of reading or ±0.1 Pascal digit, whichever is greater.

The DM4 is calibrated for use with the E3 blower door, the Infiltec

DL1 duct leakage tester, and Pitot tubes. Flow, pressure, and leakage

area can be displayed in US, metric, or mixed units. Electronics are

110VAC/60 Hz. Options include software, fan covers, and door expander kit.

Enclosure integrity test capacity for one E3 fan is up to

5150 m3 (182,000 ft3) for FM-200,

2500 m3 (88,000 ft3)) for INERGEN,

4500 m3 (159,000 ft3) for HALON 1301,

5840 m3 (206,000 ft3) for NOVEC-1230,

2500 m3 (88,300 ft3) for ARGONITE, and

4700 m3 (166,000 ft3) for FE-25.

Calibration certificate included that meets NFPA 2001-2012, and ISO 14520-2012 standards.

Multiple fan systems are available for larger enclosures.

Specifications

| $3,245 |

| E3-A-DM4-220 | Same as E3-A-DM4-110, except for 220VAC/50 Hz electronics. | $3,245 |

| MODEL | DESCRIPTION | PRICE |

|---|---|---|

| S220 Smoke Pen Kit |

|

$47.95 |

| S221 Smoke Pen Refills | Regin S221 SmokePen Refills: 6 wicks to refill the S220 Regin Smoke Pen. Order. | $34.95 |

| E3-CASE-FAN | Carrying Case for E3 blower door fan (constructed of durable rip-stop water-proof black nylon) | $129 |

| E3-FAN-COVER | Nylon cover for sealing off E3 fan opening, elastic edge. | $25 |

| E3-A-CROSS-BRACE | Extra aluminum cross brace for E3 standard sized door for increased stability. | $75 |

| E3-DOOR-EXPANDER | Aluminum Door Frame Expansion Kit for E3 to increase Door Width to 50.5 inches and Door Height to 97.0 inches. Includes case and second cross brace. Does not include Expander Door Cover. | $551 |

| E3-EXPANDER-COVER | Expander door cover, blue nylon, elastic edge, fits 1 E3 fan. | $180 |

| E3-DOOR-WIDER | Aluminum Door Frame Width Expansion Kit for E3 to increase Door Width to 50.5 inches. Includes case. Does not include Wider Door Cover. | $461 |

| E3-WIDER-COVER | Wider door cover, blue nylon, elastic edge, fits 1 E3 fan. | $180 |

| INFILFIRE Software | 2023 UPDATE AVAILABLE NOW: InfilFire software is compatible with Windows XP to 11. Its calculations are compatible with NFPA-2001 standard 2023 version Annex D for Clean Agent Enclosure Integrity testing, and updates to the InfilFire can be downloaded from the internet. All clean agents, plus CO2 and Halon 1301, are included. InfilFire Includes Peak Pressure calculations, and a 50 Pa test option. The office version of InfilFire comes with 3 installations. If you require more installations, an Enterprise version is available. There is no limit on fans or technicians. An enterprise version is available if you require more installations. Download a free full feature demo. | $900 |

| BD-DOS-FIRE Software | Infiltec DOS PC Software for NFPA-2001 standard, version 2000, Annex D for Clean Agent Enclosure Integrity test byBlower Data Analysis I includes ggents: Halon 1301, C02, FM-200, INERGEN, CEA-410, NAF-SIII, FE-13, Argonite, FIC-1311, Argon, FE-241, FE-25 and NOVEC. Also Includes pre-test prediction to estimate how many blower doors will be needed for test. (compatible with all versions of Windows by the use of the DOSBOX software, includes pdf manual, no limit on installations, and no limit on fans). | $300 |

For testing larger spaces, the Infiltec Model E3-3FAN-STACK generates higher air flows by stacking up to 3 E3 fans in each door jamb.

![]()

Training Certification.

Training on NFPA 2001 Standard enclosure integrity test theory, equipment and software is available at your location or via the internet. Online training is approximately 3 hours, generally done in two 1.5 hour sessions.

The Infiltec Fire Enclosure Integrity Training Certificate is signed by trainer David Saum, cofounder of INFILTEC who is the co-inventor of the fire enclosure integrity test method, was co-awarded the US patent 5,128,881 Means and Methods for Predicting Hold Time in Enclosures Equipped with a Total Flooding Fire Protection Fire Extinguishing System, has worked on R&D for fan test technology and standards for over 30 years, and who is the head of the Infiltec training programs.

For a worldwide list of some of the enclosure integrity test contractors trained by Infiltec, click here.

![]()

Calibration and Repair.

Infiltec offers factory recalibration and repair for Infiltec instruments, and most other manufacturer's equipment. Note that recalibration requires that both the fan and the gauges be shipped to the Infiltec factory. If necessary, we can generally arrange for one-day turnaround on your recalibration.

![]()

About Infiltec

Today the Infiltec Inc. factory in Waynesboro VA builds air leakage test equipment that is used worldwide for pressurization leakage testing of buildings and total flooding fire protection enclosures.

David Saum of Infiltec, has been active in NFPA, ASTM and ASHRAE standards committees. He holds several patents for air leakage measurement technologies. He is the author of many papers on radon mitigation, air leakage testing of total flooding fire system enclosures, and air infiltration testing for energy conservation.

.

![]()

Links to Halon Alternative Resources on the Web

This page copyright © 1996-2023 by

Infiltec Inc.,

all rights reserved.

It was last updated on July 31, 2023.

|

|---|